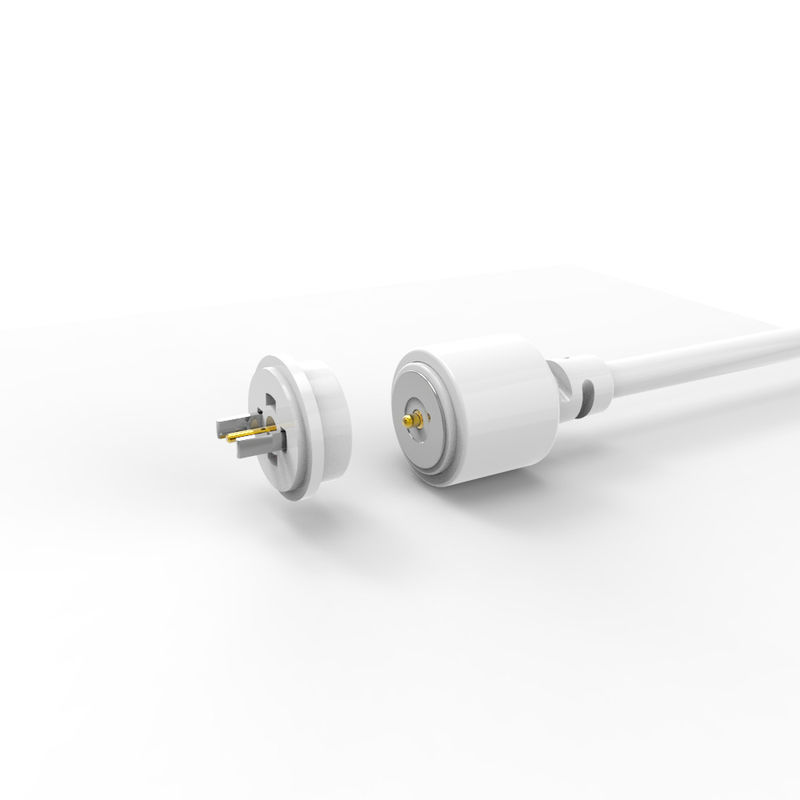

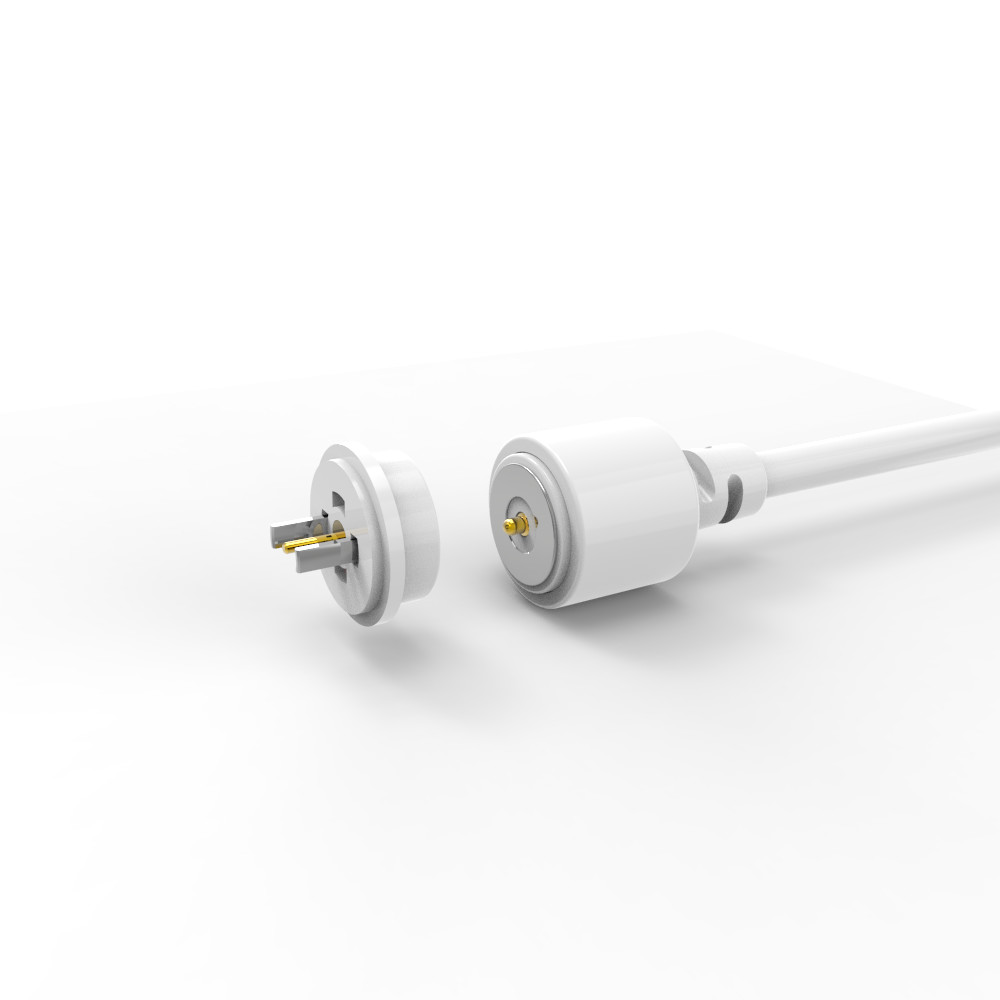

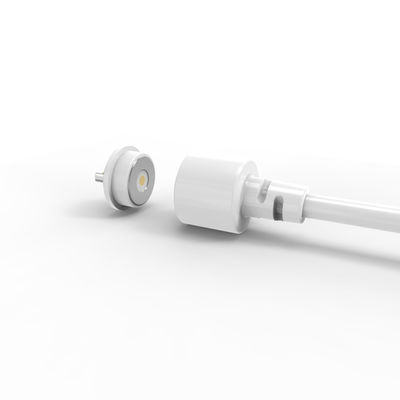

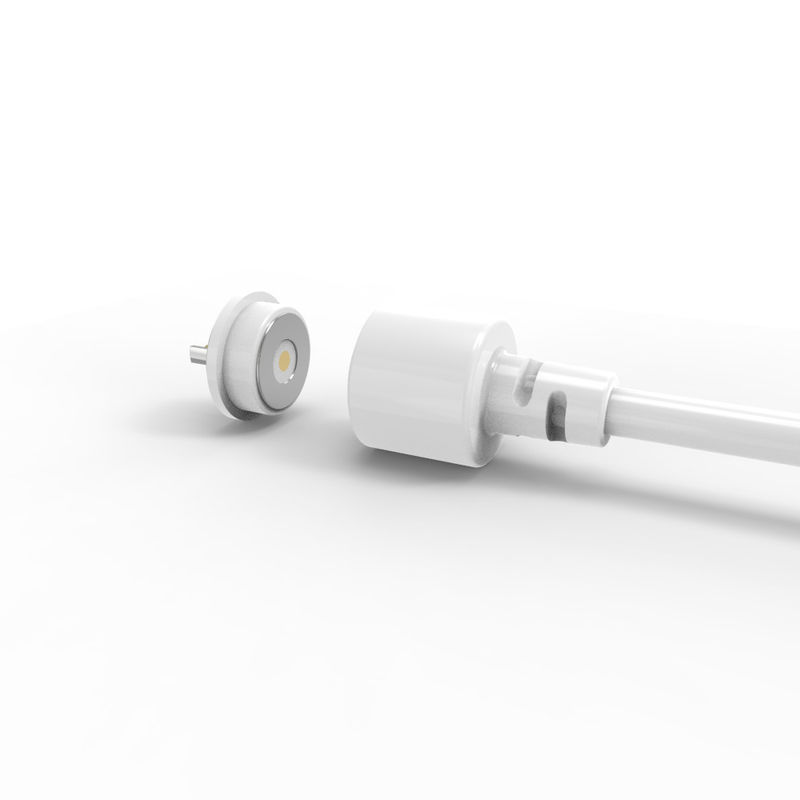

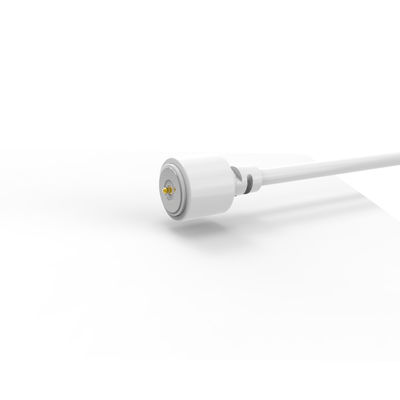

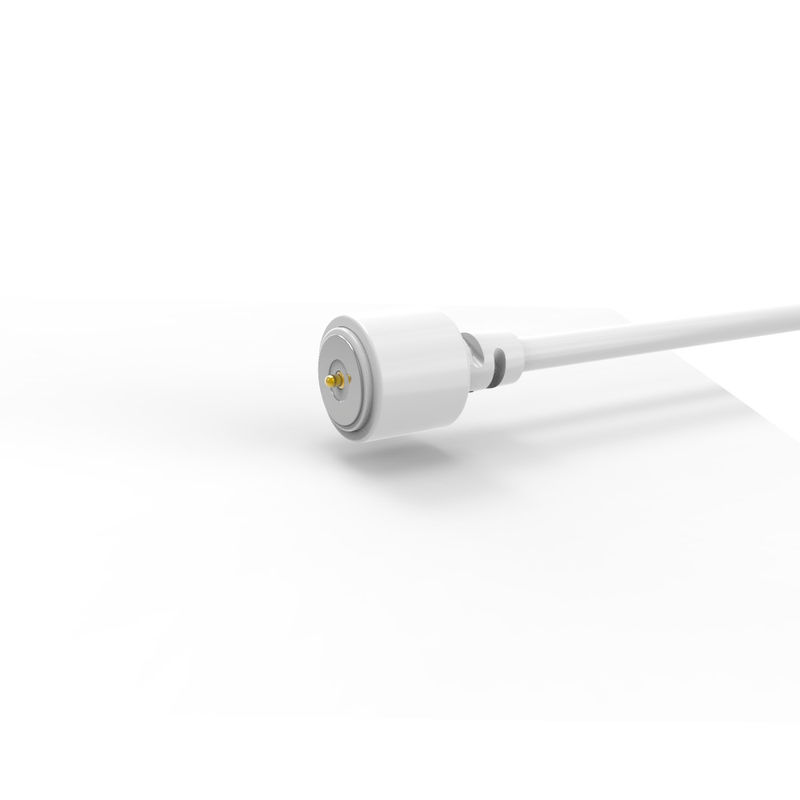

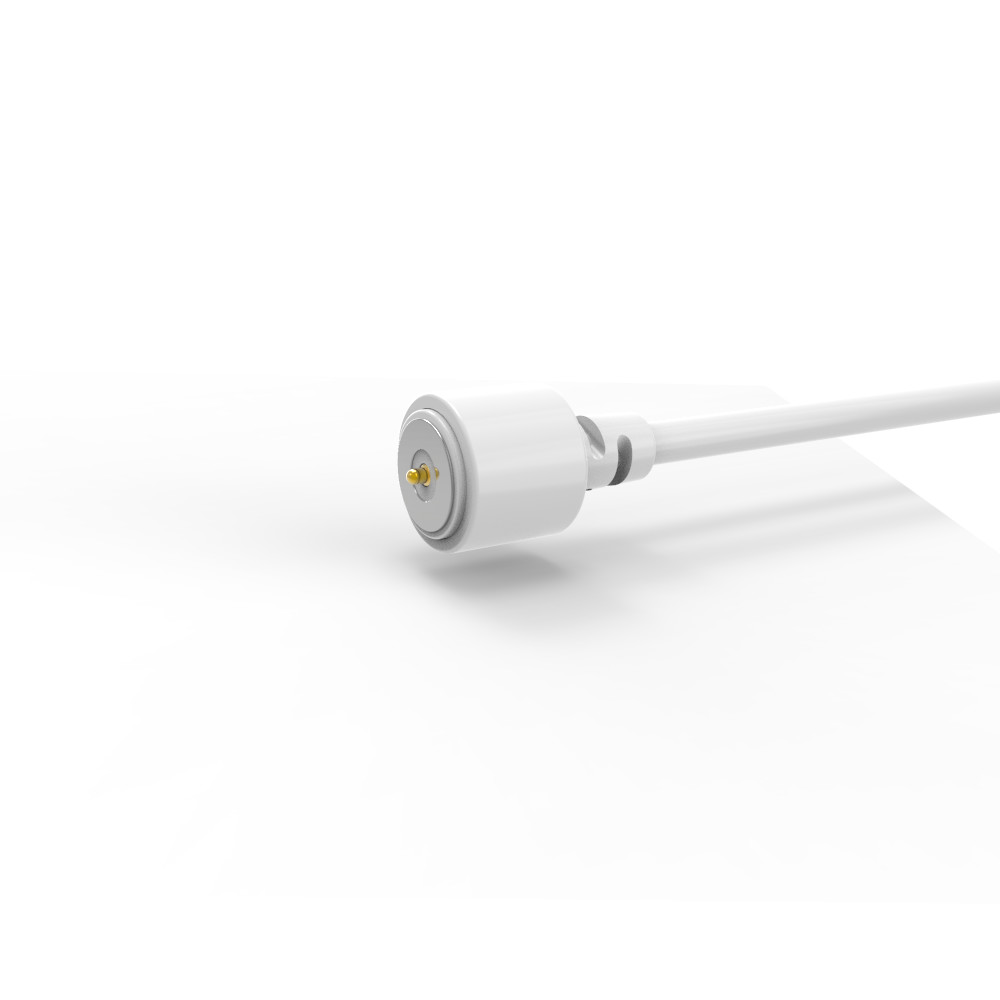

White LCP housing dia.8.0mm circular male female magnetic cable connector.

UPE is professional magnetic connector & magnetic cable connector manufacturer.

We have our own professional designers to meet any of your requirements and provide magnetic connector customization service. Different magnetic pogo pin connector products and solutions can be designed according to different customer needs.

We have been adhering to continuous technological innovation and high-quality products as the core of the company's development, a professional and experienced technical team has more than 15 years of experience in the relevant connector industry.UPE have many years of work experience in product development and manufacturing.UPE ensure product quality during product design, development and manufacturing. At the same time, it can also provide customers with technical support such as synchronous development.

The production plant area is strictly implemented in accordance with the 7S standard, and the dust-free workshop is used for production operations and the working environment is clean and tidy. We strictly implement quality control in accordance with ISO90001 quality management system standards.

The products are mainly sold to Europe, the United States, Canada, Australia, and developed countries and regions in Asia.

Male magnetic cable connector:

1. Materials & Construction (Premium & Durable):

Pogo Pins: Brass core with high-end plating (60~100µ" Ni under 5µ" Au) ensuring superior corrosion resistance, low contact resistance, and long-term reliability.

Housing: White LCP+30%GF UL94 V-0

Magnet: NdFeB N52 (Ni-plated) – Industry-leading magnetic strength (N52 grade) for secure mating with corrosion protection.

Cable & Jackets:

Cable: OD 3.0mm, 2-core (43x0.08mm tinned copper strands).

Connector & Wire Jackets: White TPE 90A – Flexible, abrasion-resistant, and aesthetically consistent.

2. Mechanical Performance (Precision-Engineered):

Spring Force: 60g ±10g @ 1.0mm working stroke – Optimized for stable contact pressure and easy mating.

Stroke: Full travel 1.2mm (working stroke 1.0mm).

Lifespan: 10,000+ cycles – Robust design for high-freque

3. Electrical Reliability (Tested & Certified):

Rating: 12V / 2A – Suitable for low-power data/power transmission (e.g., wearables, IoT devices).

Contact Resistance: ≤50mΩ per pin (ensuring minimal voltage drop).

Testing: 100% open/short circuit tested + 48H salt spray (validating corrosion resistance).

Compliance: ROHS/REACH – Environmentally safe for global markets.

Female magnetic connector:

Key Components & Materials:

1.Pins (Electrical Contacts):

.Base Material: Lead-free Brass Alloy C6801 (Higher copper content than standard brass, offering better conductivity and corrosion resistance).

.Plating: Same as male - Min 5µ" Gold (Au) over 60-100µ" Nickel (Ni). Ensures excellent corrosion resistance and low contact resistance.

2.Housing (Main Plastic Body):

.Material: Identical to male - White LCP+30%GF UL94 V-0

3.Shell (External Metal Structure):

.Material: Lead-free Brass Alloy C6801.

.Plating: Nickel (Ni). Provides corrosion protection and a consistent finish. This is a significant structural difference vs. the male connector.

3.Magnet:

.Type: Identical to male - NdFeB N52 (Strongest common grade).

.Plating: Nickel (Ni). Essential for magnet corrosion protection.

Electrical Specifications:

1.Operating Voltage: 12V DC (Same as male).

2.Operating Current: 3.0A (Critical Difference - Higher than the male's 2A rating).

3.Contact Resistance: Max 50mΩ per pin (Same specification as male).

4.Testing: 100% Open & Short Circuit Test (Standard quality control).

Compliance & Reliability:

Environmental Compliance: Explicitly RoHS & REACH compliant.

Corrosion Resistance (Salt Spray Test): 48 Hours (Same as male, indicating good environmental resilience for the plating/materials

Product application description (not limited to the following):

1.Plug-in welding PCBboard;

2.Forming and encapsulating after welding wires;

3.A transfer terminal of that PCBboard can be adde;

4.Mlding injection molding of embeddable mould;

5.Wires can be bonded directly.

Circular 2Pin Magnetic Cable Connectors Parameter:

|

Name

|

Magnetic Cable Connector

|

|

Type

|

Male/Female

|

|

Pin

|

2pin

|

|

Diameter

|

8.0mm

|

|

Wire

|

TPE

|

|

Cable length

|

1000±20mm

|

|

Color

|

White

|

|

Pogo pin/TurningParts

|

Lead-free C6801

|

|

Magnet

|

N52 NdFeB Plating Ni 15-20um

|

|

Housing

|

White LCP+30%GF UL94 V-0

|

|

Spring force

|

60g±10g,at 1.0mm working storke

|

|

Full storke

|

1.2mm

|

|

Mechanical life

|

10000 cycle Min..

|

|

Current

|

2A Max

|

|

Voltage

|

DC 12V

|

|

Contact resistance

|

50mΩ Max (PIN).

|

|

Operation Temperature

|

-25℃to +80℃

|

|

Salt spray test

|

48H

|

|

Certification

|

ROHS or REACH compliant product

|

|

Test

|

100% open and short test

|

Circular 2Pin Cable Connector Technical Drawing

Circular 2Pin Female Magnetic Connector Technical Drawing

Recommended pcb layout

Advantages of Magnetic Connector:

●Humanize design of automatic adsorption connection experience;

●Humanized anti-fall: it is easy to remove from the charging interface, and it is not easy to remove the device;

●Life time: up to 100,000-200,000cycle;

●Waterproof design: the female end of the device can be dustproof and waterproof (IPX8);

●Fast charging time: 5A-10A magnet connector design withstands large current transmission;

●The appearance of the magnetic connector can be matched according to the design of the customer's application device;

●Product anti-short circuit structure design and foolproof;

●Realize high frequency signal transmission,can replace the traditional USB2.0 HDMI 1.3 function Video&Audio signal transmission

Products application:

1.Wearable devices, intelligent positioning equipment, children's smart wristbands, smart watches, wearable mobile phones,Bluetooth headsets, etc.) data cable, charging cable, magnetic strip wire end connection

2.Medical equipment,wireless equipment,data communications equipment,telecommunication equipment,Automation and industrial equipment,audio-visual equipment

3.Aviation ,aerospace electronic,military communication

4.Automotive,car navigation,test and measurement equipment

5.Consumer Electronics(mobile phones,tablet computers,Bluetooth headsets,camera,watch,portable consumer electronic products and many other electronic fields.)

Why choose us ?

1. Professional customization service

2. Fast sample production capability

3. Strict quality control system

4. Processing with imported components

5. High-precision test equipment

6. Reasonable cost control procedures

7. Product environmental standards

How to place the magnetic cable connector order

Step 1: Submit Your Requirements

Provide these key details:

✅Connector Type: e.g., Charging-only, Data+Power (USB-C/HDMI), Pogo Pin, Hybrid

✅Quantity: Estimated annual volume (e.g., 50K units/year)

✅Customization Needs:

.Shape/size (e.g., circular Ø5mm, right-angled)

.Current rating (e.g., 8A fast charging)

.IP rating (e.g., IPX8 waterproof)

.Signal type (e.g., USB 2.0 + 12V power)

Aesthetic (color, branding, surface finish)

✅Technical Specs: Operating voltage, mating cycles, operating temperature range

Step 2: Quote & Agreement

UPE provides:

.Unit pricing (volume discounts for 5K+ orders)

.Lead time (prototyping + mass production)

.Payment terms (e.g., 50% deposit, 50% pre-shipment)

Finalize: MOQ, delivery schedule, packaging

Step 3: Confirm Order & Pay

Sign a PO or formal order agreement

Pay securely via:

.Bank Transfer (SWIFT/TT)

.PayPal

.Letter of Credit (for bulk orders)

Step 4: Production & Shipping

✅Prototyping: 5-7 days (sample approval before mass production)

✅Mass Production: 15-20 days (flexible scaling)

Shipping:

.EXW

.Trackable logistics (DHL, FedEx, sea freight)

Step 5: Quality Assurance

✅Pre-shipment: UPE provides QC reports (IP testing, continuity checks)

✅Post-delivery: Inspect for:

.Dimensional accuracy

.Signal/power performance

.Finish consistency

Shipping

Any question, please send to union@upetech.net

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!